|

WUHAN REMCOR TECHNOLOGY CO.,LTD

|

Coil Sheet Production System

| Price: | 4000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

As one of laser cutter suppliers, we will do our best to meet all the needs of customers.

Remcor Technology offers a range of sheet metal coil line machine solutions for coil sheet processing. Including the coil feeding system, levelling system, pressing or bending system, punching or slitting system, shearing system, laser cutting system. We are the first laser machine manufacturer in the field of entire sheet metal coil line handling solutions.

How Does Remcor Sheet Metal Production System Processing

Coil Loading Trolley

Max loading capacity: 9 tons. This sheet metal coil line machine can be tailored to loaded 1 coil and 1 coil in storage system next to it.

Decoller

Hydraulic to support the unwound coil sheet. Our Standard line can support the Max loading capacity with 9 tons, and the decoil device can also be customerized according to your drawings and demands.

Levelling Device

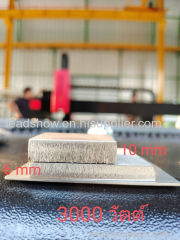

The coil sheet can be straightened and remove the tensions with the leveling system. The straightening rolls were driven by motors which will be designed according to the material type and thickness range. The roll feeder is for thin (0.5-15mm) and narrow (1250mm) coil materials, and it is mounted on a solid steel frame. Both upper and lower feeding rolls are driven by an AC servomotor with a precision gearbox and timing belt transmission.

Punching Unit

The Punching is done by tools set in two traversing tool cassettes, with the punching stroke done by a single ram plate. Punching, and piercing are standard features. The same principle as Pivatic.

Pressing Or Bending

Bending system can be applied after shearing. Together with the Robert which can realize unman loading and unloading.

Optional Device

The auto laser cutting machine can also be applied after the leveling device which can make the system with more flexibility. And also, the Soldering machine can be connected with the cnc panel bender.

Application of Sheet Metal Coil Line

Steel furniture industry, electric cabinets, elevators, food service equipments, refrigerators, mechanics and machinery.

Automobile, aluminum or stainless-steel products by structural steel laser cutting, and other industries with high surface quality requirements.

As one of laser cutter manufacturers, we will do our best to meet all the needs of customers.